Have a great weekend!

Friday, April 29, 2011

Thursday, April 28, 2011

Shiny

Just have the fork to finish up the fork tonight and then off to paint tomorrow. Thanks, Joe!

All of my DT lugs for the dirt road and cross bikes will be back from the engraver tomorrow. Then it will be dirty bike central around here.

All of my DT lugs for the dirt road and cross bikes will be back from the engraver tomorrow. Then it will be dirty bike central around here.

Wednesday, April 27, 2011

Tuesday, April 26, 2011

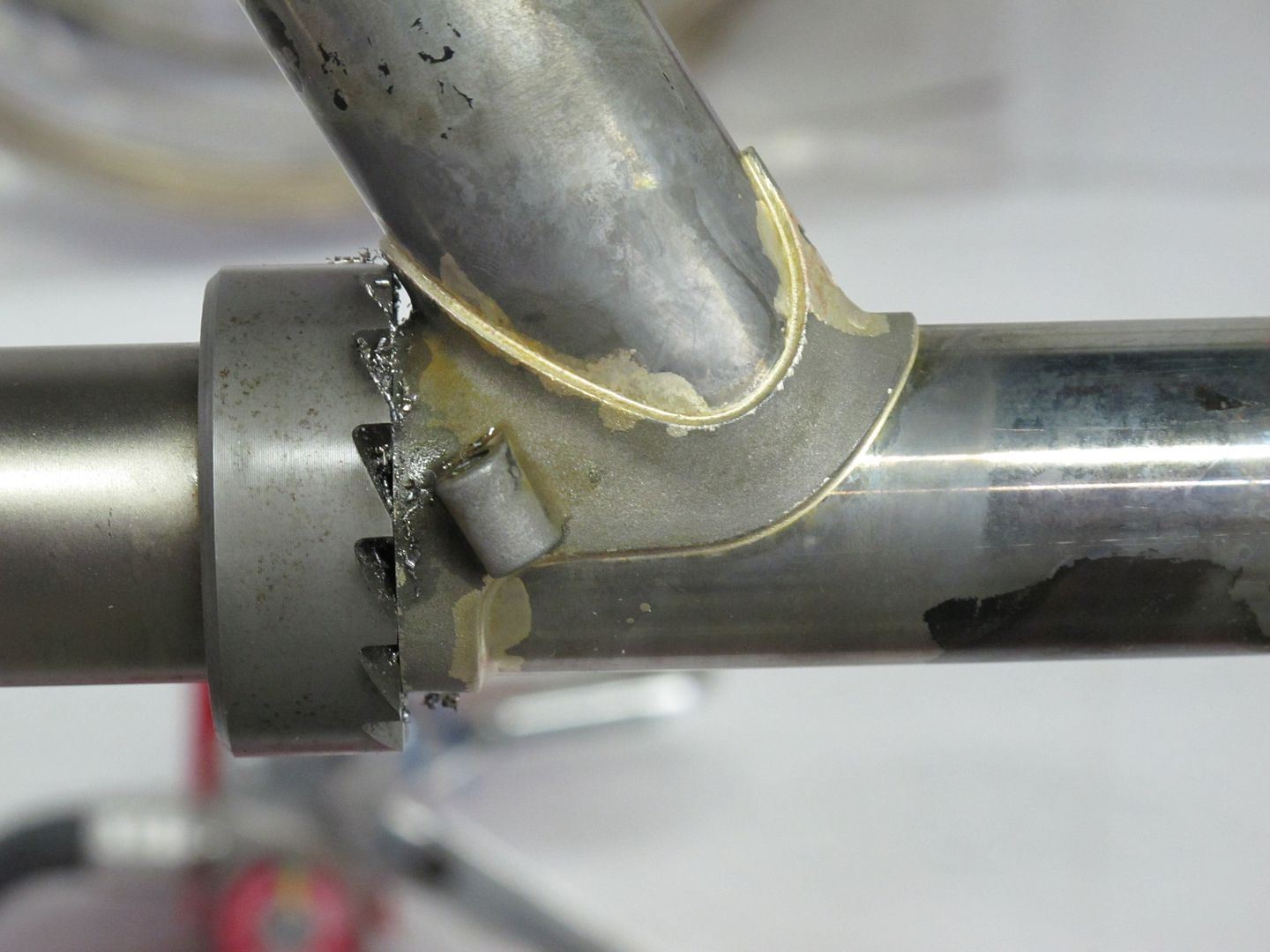

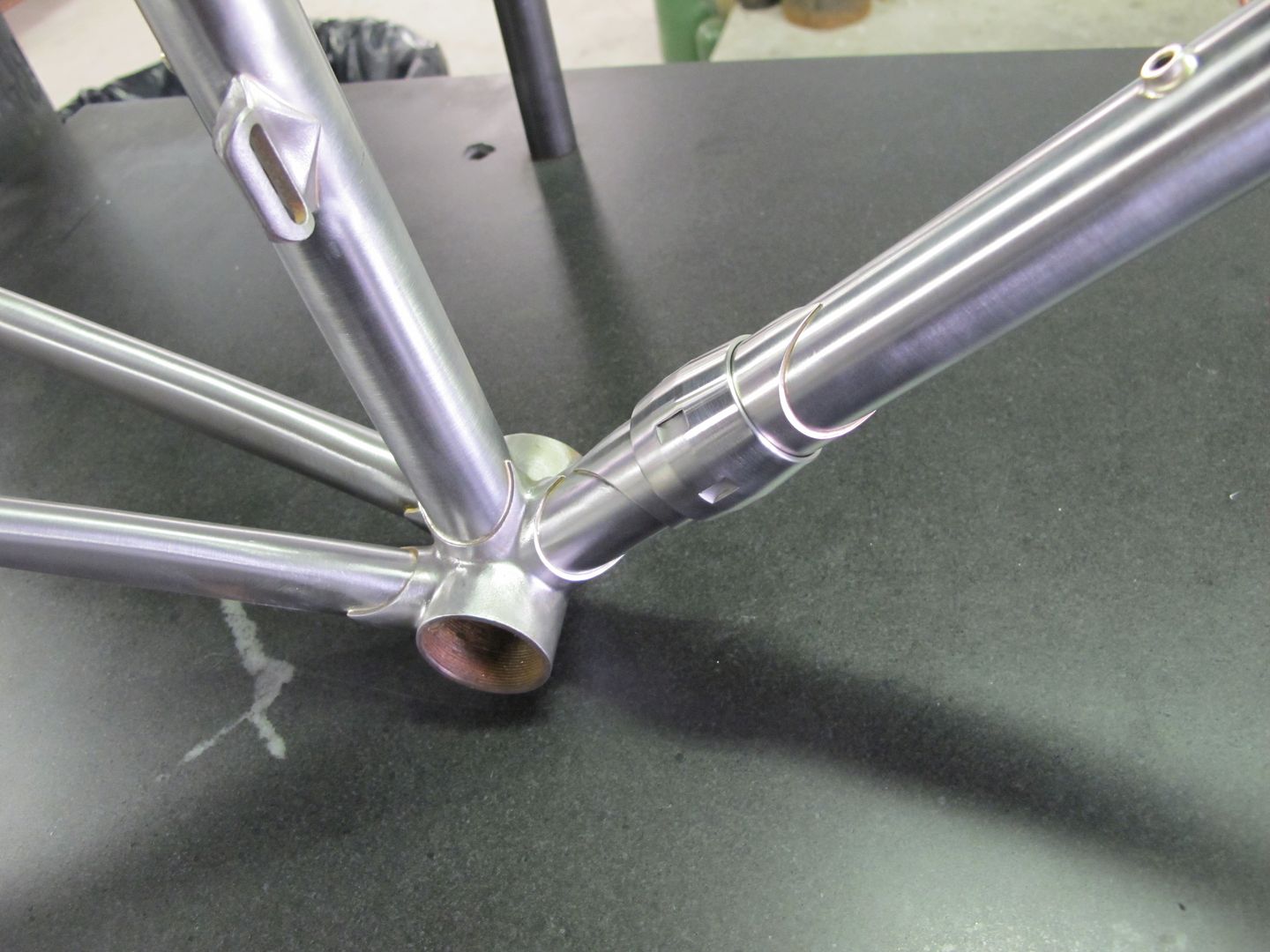

S&S Road

This was a fun one to build after doing 5 straight 60+cm frames! Since the S&S couplers add quite a bit of stiffness to the frame, we went with standard diameter tubing and a nice light set of stays. We also set up the bike with maximum clearance on the brakes and fender mounts for the spring mess.

Many thanks, Chris and Mike!

Many thanks, Chris and Mike!

Saturday, April 23, 2011

Day 3: Lincoln Electric's GTAW (TIG) welding class

Day 3 kicked off with a lecture on AC welding on aluminum and magnesium. We only practiced on aluminum, but the techniques and machine setup are similar between the two materials. Both materials form oxides on their surface that melt at much higher temperatures than the parent metal underneath. These oxides need to be removed while welding, and the electrode positive half-cycle of the alternating current is what breaks them up. We discussed the AC balance on the machine and the pros and cons of more cleaning action (balance towards more electrode positive) and more penetration (balance towards more electrode negative). We also discussed the frequency of the AC cycle, and how a higher running frequency results in a tighter arc and deeper penetration. It's amazing all of the technology that goes into AC welding and the resulting flexibility the adjustments provide. I made quite a mess of some nice coupons of 6061, but I was having fun doing it. I also did a few more tubing samples towards the end of the day.

Butt weld

Added a T joint

Lap welds

Started getting out of hand. See that big puff of black? Yeah, I hit the tungsten with the filler rod.

Edge weld

Outside corner

Trying to get into a tight spot. Well, maybe a tight spot for a beginner. Note the TIG Finger Heat Shield in the background. Very handy.

Tubing attempt #4

Tubing attempt #5

Tubing attempt #6

Tubing attempt #8

That's about it for day 3. I've been adding more photos to the Photobucket gallery HERE. Thanks for reading!

Butt weld

Added a T joint

Lap welds

Started getting out of hand. See that big puff of black? Yeah, I hit the tungsten with the filler rod.

Edge weld

Outside corner

Trying to get into a tight spot. Well, maybe a tight spot for a beginner. Note the TIG Finger Heat Shield in the background. Very handy.

Tubing attempt #4

Tubing attempt #5

Tubing attempt #6

Tubing attempt #8

That's about it for day 3. I've been adding more photos to the Photobucket gallery HERE. Thanks for reading!

Wednesday, April 20, 2011

Day 2: Lincoln Electric's GTAW (TIG) welding class

Day 2 was all about stainless. We began the day at 8am with approximately 90 minutes of lecture. We started with some basic metallurgy and went over the different families of stainless. We then talked about some of its physical characteristics and really focused on its thermal conductivity and why stainless wraps the way it does. Then we went into machine settings and techniques. Pulse was introduced and we were encouraged to experiment with high frequency pulse to reduce heat input and (hopefully) warpage. A little Q&A and then we were off and running. Bob cruised around all of the booths and did some demos for us. But really, it's been all about booth time. I've been skipping lunch and staying late. The six straight hours of uninterrupted practice has been fantastic. Here are some photos. Please be kind. With only a tiny bit (maybe an hour total) of previous experience, these are some of my first attempts at welding of any kind. The entire album can be seen HERE.

The booth.

Lincoln InvertecV205-T

16 gauge carbon steel butt welds

16 gauge carbon steel T joint

16 gauge stainless butt weld

stainless T joint

my first tubing sample attempt

There's a lot of photos showing a ton of nasty welds in that gallery link I posted above. Fun stuff.

Thanks for reading!

The booth.

Lincoln InvertecV205-T

16 gauge carbon steel butt welds

16 gauge carbon steel T joint

16 gauge stainless butt weld

stainless T joint

my first tubing sample attempt

There's a lot of photos showing a ton of nasty welds in that gallery link I posted above. Fun stuff.

Thanks for reading!

Subscribe to:

Posts (Atom)